Yeah so maybe you saw a fun little video of this

project over on

my Instagram

or maybe over on

my TikTok

but it appears, according to my records, I have yet to share it here.

Doh, what an oversight! Yes, I made slatted wood wall panels for

our

kitchen

doorway.

Or, see it here...

And it's a freakin' cool glow-up indeed, right?! If I do say so myself.

I will say too, I was concerned about doing it up fancy pants in this doorway

because it's

our daily egress

in and out, the way to

the pantry,

the only access to

the back stair, and out to

the yard

and garage.

Meaning, Mr. Tinkles-a-Lot Finn goes back and forth and back and forth on the

regular. Not that he's a walking Finn-in-a-china-shop, but he does have

nails.

Meaning, Mike, he is a bull in a china shop and as we well know, he did go and

break my original Puppy Gate, Deck Style

so I'd make

a nicer one.

Mostly though this is where all my project supplies pass through.

All. Along with groceries, trash, stuff to hang out on

the deck with or in the yard....you get the gist. Everything passes by

here with the potential for damage.

But, I also figured this spot needs a spiffing up and if it's spiffy, maybe

we'll all take some extra care. And so far so good. Whewww!

So, it was simple project but it did involve lots of math which generated

headaches per usual. Thank goodness for

AutoCAD.*

Not that you need CAD for this project; you don't. You can definitely

draw it up by hand on paper or if you're a math whiz, probably just figure it

all out in your head.

Righty-o! Fun project this was. Or, I should say while a bit

repetitive with some yawn moments, the final project is fun!

Ok, so how did I create this slatted wood wall panel kitchen doorway glow-up

business?

First? Measure. Measure lots.

I waffled on trying to remove the existing fiberboard that surrounds the door

opening but noticing a window where it's bowing (yes I need to fix that), I

see that it's likely half inch. I deduced I'll make it work rather than

make things more aggravating complicated for myself.

Too, this was in the midst of

several health rollercoaster rides for Finn; my time and attention were on him.

Next, design it. Heh. You know this is problematic for me --

so many options! Goodness. I can't find all my previous

posts outlining design decision struggles but they are here, haha.

So yeah, that took a bit to figure out but I resolved simpler was better.

After hitting up the computer to design and redesign and do the

math

more efficiently, I realized a pencil and a ruler and

drawing a portion directly on the wall would help me. And it did, so I highly encourage drawing on walls.

Oh, and because I was staining the wood and the existing fiberboard is

painted, I decided to make a backing panel and adhere my design to that which

also makes for painless un-installation if need be.

Yes, this project is easily removable any time. Niiiice.

I realize multiple layers cost me an inch of door width; so be it.

Sacrifices must be made for good design!

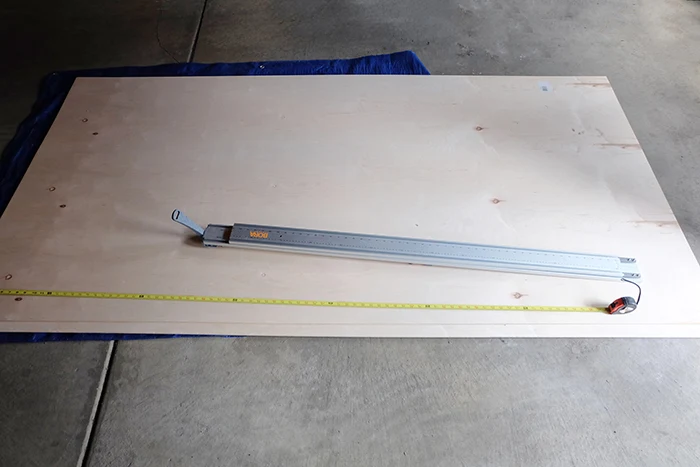

Ok! Off to Menards I ran for quarter inch maple veneer plywood.

Nothing like driving

a little hatchback

in the wind with giant four by eight foot sheets flailing on top.

Out in the garage, I made the mess and use of

my folding workbench

for the main cutting. Thank goodness I had gifted myself that

Bora NGX clamping edge* as I was slicing a zillion and one 1 1/8" wide, 8' long strips, yes, 1

1/8", yes math ouchie, out of that plywood.

For sure, a table saw. I know. I am still table saw averse. Not the most efficient to be doing this with merely my

compact saw* but I made my bed and I will lay in it.

Back

downstairs, it was time to finalize cuts and assemble these bad boys.

Sure, not gonna lie, assembly was quite labor-intensive and drearily

repetitive at times, the latter of which I don't always have patience for.

But! This was going to be awesome so head down and grind it out.

Opted for a truly clean look, meaning no nail holes and patching and schnizz

because who's got time for that so I went with wood glue* to apply the design slat pieces to the solid backing piece.

First went on the longer vertical pieces. After measuring for length,

trimming, and sanding every edge with a wee sanding block,* it was glue glue glue, brush brush, some tiny spring clamps* on the ends, and bam, nice.

I used paint stir sticks as spacers for an eighth inch gap between each wood

slat. Super handy, those paint stir sticks, amiright?! And then cans and bottles or whatever to weigh things down

until the glue stuck.

Now I could figure out the exact length of the little horizontal pieces,

which, eh, I should've used different

scrap wood

to help me with that but, I got it.

After cutting and cutting and cutting long strips into little strips then

oodles more sanding, it was slatted wood wall panel kitchen doorway glow-up

assembly home stretch time. Woo!

Easy peasy again, just use something like a slightly water-wet chip brush* to spread the glue evenly across the entire surface of the bitty wood

pieces and plop them on. Again too, with paint stir stick spacers.

Panel one done! Omg, heh, finally. It was damn cool to see it out

of my brain and in maple veneer plywood existence.

Right, so yeah, just keep on keepin' on here for panel two and the doorway

ceiling piece. Glue, plop, space, weight, glue, plop, space, weight, and

my slatted wood wall panels were done.

Lastly, stain and seal. Here I employed WeatherWash* aging stain in

Walnut* and their

Dead Flat varnish.* This stain is so dang freakin' cool. You slosh it on and as it

dries, it ages the wood. Yes, it gives the wood an aged appearance.

I used it on

the master closet shelves. Super nifty, right?!

Three coats of varnish and now it was back to math because I built these long.

Can always trim off but ya can't add back on.

Back in

the kitchen, I

measured a bazillion times

for the ceiling piece as that was going in first. What I did was trim

the panel to length, well sorta, it took a couple tries, and then set the

depth on my compact saw to a quarter inch.

What I was doing here was trimming the glued design pieces off to leave the

back piece exposed, like an L so the side panels would slide, slot in and gosh

golly, hopefully everything will line up.

After that, with the

pneumatic nailer, tacked it on.

Backed away slowly, about you-know-what my pants at how cool this looked.

|

| It's up! It's staying! And oh so stylish! |

So after trimming up the side panels multiple times because no matter what

measurement I took, it was always wrong, I jammed the side panels in.

They are suuuuper snug.

A few tacking nails to hold them on and omg....voilá....I had myself a

freaking awesome slatted wood wall panel kitchen doorway glow-up like no

other.

Holy sh*t was I excited. I still am. I love walking through here!

Did everything line up perfectly as I envisioned? Ehhh, not quite but

heh if you're only glancing and not staring, you'll not notice. I will,

and do at times, but there wasn't much I could do. Somehow math was

again against me.

So there we have it! It's a gorgeous Slatted Wood Wall Panel Kitchen

Doorway Glow-Up. Rockin' fantastic, I love it!

If this project got you going, imagine what you could do. Download The $100 Room Glow-Up Guide and see what’s possible.

*The AutoCAD link is an AutoDesk affiliate link. The Bora NGX

clamping edge, compact saw, spring clamps, and WeatherWash products are

Amazon affiliate links. The sanding blocks and wood glue are Lowes

affiliate links. The chip brushes are a Home Depot affiliate link.

Mwah, thanks! Please see the "boring stuff" tab for more

info.

Oh my!!! This looks amazing!! I wish I had a place in my home to do this.

ReplyDeleteOh thank you!! Yes, find a spot!

DeleteIt looks professional and it's beautiful. I believe we appreciate things more when we use our own ideas and dress up a home instead of just plain paint. My daughter is an artist and she does such lovely creations that are so different. Good job.

ReplyDeleteThank you very much! Indeed, you are correct, things we come up with and create are much more valued. I bet your daughter is fabulous! Thank you!

DeleteBeautiful but you should tone down the editorial and show more of the process you’re doing (measuring, gluing, spacing, etc). And a supply list. We all have to recreate the wheel to create our own. A picture alone would have sufficed for that! But I do love it and will try to find a place in my new home….

ReplyDeleteThanks for the tips! If you watch the video, the process is shown which is why the photos show less than usual and the materials are listed throughout the post. Every person’s project will be different with different wheels to recreate but I hope you’re inspired.

Delete